We Design & Build High-Efficiency Boiler Economizers – Saving Waste Energy, Cutting Costs

We Design & Build High-Efficiency Boiler Economizers – Saving Waste Energy, Cutting Costs!

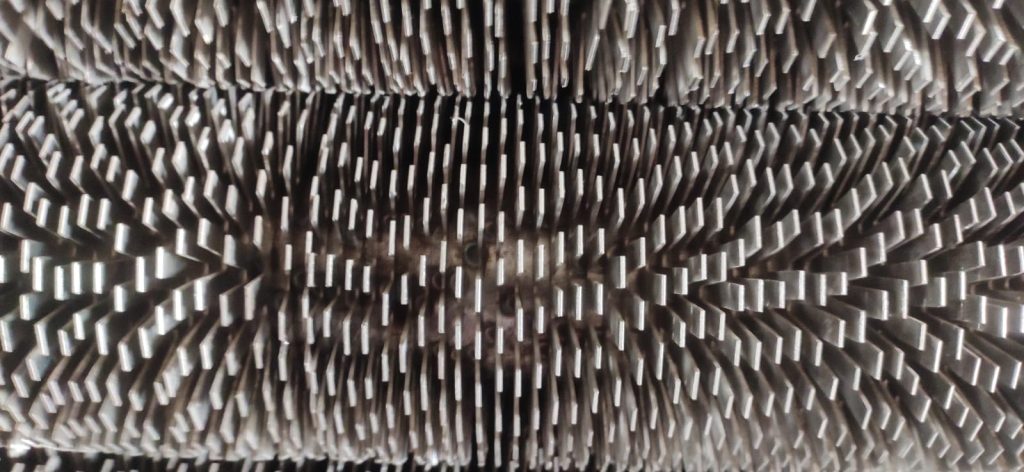

Boost Your Boiler’s Performance with Our Advanced Serrated Fin Economizer!

Why Our Economizers?

- ✅ Serrated Fins → 30% more heat transfer than smooth tubes.

✅ Custom Designs for high-pressure/high-temperature boilers (1–50 ton capacity).

✅ Proven ROI – Payback period as low as 6–18 months. - ✅ Wide Capacity Range → 1 Ton to 50 Ton (Custom Solutions Available)

✅ Built for High Pressure & High Temperature Operations

✅ Key Benefits:

-

Maximize Fuel Savings (Lower Operating Costs)

-

Reduce Emissions (Eco-Friendly Compliance)

-

Extend Boiler Lifespan (Durable Construction)

***Technical Specifications

- Pressure range- 4 bar to 100 Bar

- Materials- MS, SS and carbon Steel

- Fin types- Serrated Fin and Cylindrical Fin, Turbine Blade Fin and cross Fin

- Temperature range- 80 deg centigrade to 150 Deg centigrade

How Boiler Economizers Cut Fuel Costs in Power Plants, Oil Mills & Textile Plants

Industrial boilers waste 20-30% of energy as hot exhaust gases. Economizers recover this waste heat, preheating feedwater and slashing fuel costs by 10-25%. Here’s how they work in key industries:

1. Power Plants: Fuel Savings = Massive ROI

-

Problem: Gas/coal-fired boilers lose huge heat through flue gases.

-

Solution: Economizers preheat feedwater before it enters the boiler, reducing fuel needed to reach operating temperature.

-

Result: A 15% drop in fuel use can save $500,000+ yearly for a mid-sized plant.

2. Oil Mills (Seed Crushing, Palm, Edible, Coconut, etc.): Efficiency = Higher Margins

-

Problem: Boilers run 24/7 for steam in sterilization, drying, and refining.

-

Solution: Serrated fin economizers capture waste heat, cutting diesel or biomass fuel consumption.

-

Result: One Malaysian palm oil mill reported 20% lower fuel costs after installation.

3. Textile Plants: Steam Cost = Competitive Edge

-

Problem: Dyeing, bleaching, and drying demand constant steam.

-

Solution: Economizers reuse exhaust heat, reducing coal/gas use by 10-30%.

-

Result: A Bangladesh textile factory saved $200,000/year with a 3-ton economizer.

Get a FREE Quote Today!

Call/WhatsApp: 01818-271791

✉ Email: selim@classicindustrialservice.com

Visit: www.classicindustrialservice.com

#BoilerEconomizer #EnergySavings #IndustrialEfficiency #SteamSystems #ThermalEngineering #GreenManufacturing